1.Why is 2,5-Furandicarboxylic Acid (FDCA) Considered the Future of Sustainable Materials?

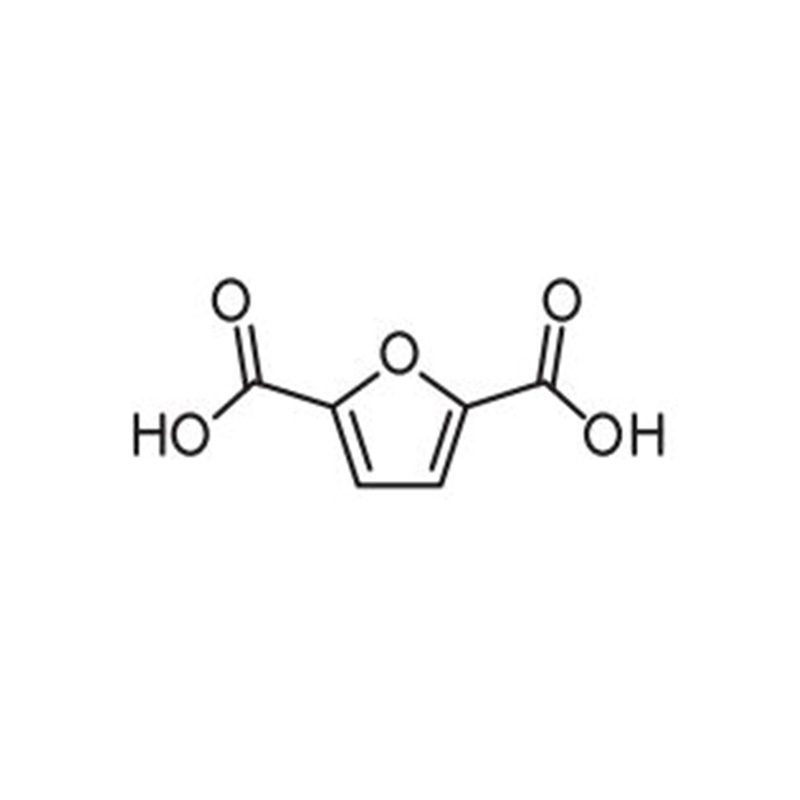

2,5-Furandicarboxylic Acid (FDCA) is rapidly emerging as a cornerstone in the development of sustainable materials, heralding a new era of eco-friendly polymers and chemicals. Derived from 5-Hydroxymethylfurfural (HMF), a platform molecule obtained from renewable biomass, FDCA is a bio-based aromatic dibasic acid that holds significant promise as a key component in creating a more sustainable chemical industry. The potential of FDCA lies in its unique chemical structure and properties, which mirror those of terephthalic acid (PTA), a conventional petrochemical used extensively in the production of polyethylene terephthalate (PET), a common plastic found in packaging, textiles, and various consumer goods.

FDCA’s structure, characterized by a rigid aromatic ring and two carboxylic acid groups, provides it with high reactivity and stability, making it an ideal substitute for PTA. Unlike PTA, which is derived from non-renewable fossil fuels, FDCA can be synthesized from plant-based sources, thus offering a sustainable alternative that significantly reduces the carbon footprint associated with traditional plastic production. When polymerized with ethylene glycol, FDCA forms polyethylene furanoate (PEF), a bio-based polyester with superior barrier properties compared to PET. PEF has been shown to have better gas barrier qualities, greater mechanical strength, and improved thermal stability, making it an ideal material for packaging applications where product shelf life is critical.

The significance of FDCA extends beyond its role as a replacement for PTA. The U.S. Department of Energy has recognized FDCA as one of the top 12 bio-based platform chemicals with the potential to build a "green" chemical industry for the future. This recognition is based on FDCA's ability to serve as a precursor to a variety of high-value chemicals and materials, including biodegradable plastics, resins, and coatings. FDCA’s versatility allows it to be used in numerous applications, from food packaging and beverage bottles to automotive parts and textiles, all of which can benefit from the shift to more sustainable, bio-based alternatives.

The market potential for FDCA is vast, driven by growing consumer demand for sustainable products and increasing regulatory pressures to reduce plastic waste and greenhouse gas emissions. As industries worldwide seek to transition to a circular economy, where materials are reused and recycled rather than disposed of, FDCA offers a viable solution that aligns with these sustainability goals. The development and commercialization of FDCA are expected to play a crucial role in reducing our reliance on fossil fuels, lowering environmental impact, and creating new economic opportunities within the bio-based materials sector.

2.How Does Zhejiang Sugar Energy Technology Lead the FDCA Market?

Founded in 2017, Zhejiang Sugar Energy Technology Co., Ltd. has swiftly become a key player in the global FDCA market, leveraging cutting-edge research and development to produce high-quality bio-based materials that meet the evolving needs of industries worldwide. Our company was established as a national high-tech enterprise in collaboration with the Ningbo Institute of Materials, Chinese Academy of Sciences, and this strong foundation has allowed us to build a robust ecosystem for the production of furan-based materials, with FDCA as one of our flagship products.

Our leadership in the FDCA market is driven by our comprehensive approach to the production and commercialization of bio-based materials. We have developed an integrated value chain system, encapsulated in our "1 high-end raw material +5 platform molecules +N high-value products" strategy. This system allows us to control the entire production process, from the initial synthesis of HMF, the precursor to FDCA, to the final production of FDCA and its derivatives. This level of integration ensures that we can maintain stringent quality control, optimize production efficiency, and respond swiftly to market demands.

One of the key factors that set Zhejiang Sugar Energy Technology apart is our commitment to innovation. We have invested heavily in research and development, working closely with leading scientists and engineers to advance the technology used in FDCA production. Our research teams are continuously exploring new methods to enhance the efficiency of HMF dehydration, improve the catalytic processes involved in FDCA synthesis, and develop novel applications for FDCA in various industries. This focus on innovation has enabled us to produce FDCA at a competitive cost while maintaining the highest standards of quality.

Our production facilities are equipped with state-of-the-art technology, designed to maximize output while minimizing environmental impact. We utilize advanced catalytic processes that not only increase the yield of FDCA but also reduce energy consumption and waste production. By adopting these sustainable practices, we are able to offer FDCA that is both eco-friendly and economically viable, making it an attractive option for manufacturers looking to transition to bio-based materials.

3.Why Choose FDCA from Zhejiang Sugar Energy Technology?

When you choose 2,5-Furandicarboxylic Acid (FDCA) from Zhejiang Sugar Energy Technology Co., Ltd., you are selecting a product that is backed by a combination of cutting-edge research, high-quality production standards, and a commitment to sustainability. Our FDCA is not just a product; it is a solution designed to meet the demands of modern industries while contributing to a greener, more sustainable future.

One of the primary reasons to choose our FDCA is the quality and consistency of our product. At Zhejiang Sugar Energy Technology, we employ advanced production techniques that ensure our FDCA meets the highest purity standards. Our state-of-the-art facilities are designed to maintain strict quality control throughout the manufacturing process, from the initial synthesis of HMF to the final production of FDCA. This commitment to quality is reflected in the superior performance of our FDCA in a wide range of applications, from bio-based plastics and resins to coatings and adhesives.

Another key advantage of our FDCA is its sustainability. As a bio-based material derived from renewable resources, FDCA offers a significant reduction in carbon footprint compared to traditional petrochemical-based materials like PTA. By choosing our FDCA, manufacturers can contribute to reducing greenhouse gas emissions and decreasing the reliance on fossil fuels, aligning with global sustainability goals and responding to increasing consumer demand for eco-friendly products. Our production processes are also designed to minimize environmental impact, utilizing energy-efficient technologies and reducing waste generation.

Zhejiang Sugar Energy Technology’s FDCA is also highly versatile, making it suitable for a wide range of industrial applications. Whether you are in the packaging industry looking to produce bio-based plastics, in the coatings industry seeking sustainable alternatives, or in the automotive sector exploring lightweight materials, our FDCA provides the performance and reliability you need. Our product’s compatibility with existing production processes and its potential for use in various high-value products make it an ideal choice for companies looking to innovate and stay ahead in their respective markets.

英语

英语 中文简体

中文简体