1. What is FDME and How is it Produced?

2,5-Furandicarboxylic acid dimethyl ester (FDME) is a vital bio-based chemical intermediate that has attracted significant interest in various industries due to its renewable origins and wide range of applications. FDME is produced through the oxidation and esterification of hydroxymethylfurfural (HMF), a compound derived from biomass sources like fructose and glucose. This production process makes FDME part of the broader trend towards utilizing renewable resources in chemical manufacturing, reducing reliance on fossil fuels and contributing to the sustainability of industrial processes.

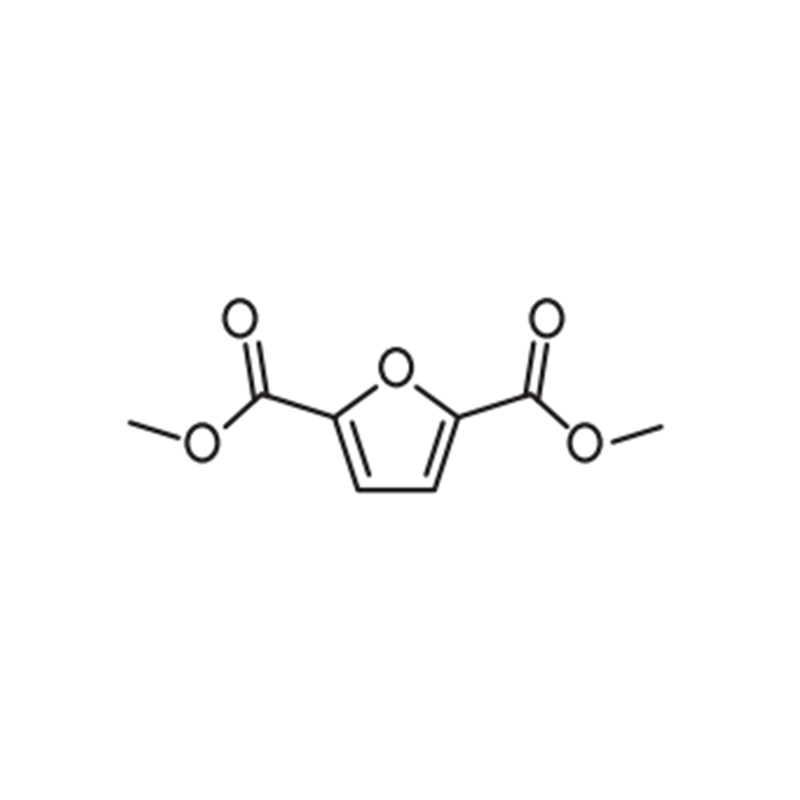

The molecular structure of FDME, denoted by the formula C8H8O5, features two ester groups attached to a furan ring. This structure imparts FDME with unique chemical properties, such as its ability to easily participate in polymerization reactions. FDME has a molecular weight of 184.15 g/mol, and its physical properties further reflect its stability and usefulness in various chemical reactions. It has a melting point of 117.6℃, indicating its solid state at room temperature, and a boiling point of 270.9℃ at 760 mmHg, showing its stability under standard atmospheric conditions. Additionally, FDME has a relative density of 1.244 g/cm³, which is typical for organic esters and contributes to its ease of handling and storage.

One of the key advantages of FDME is its stability, particularly when stored in sealed containers at room temperature. This stability is crucial for maintaining the integrity of the chemical during transportation and storage, making FDME a reliable raw material for various industrial processes. The production of FDME is a relatively straightforward process, often involving catalytic oxidation of HMF followed by esterification. This process not only yields a high-purity product but also aligns with the principles of green chemistry, reducing the environmental impact of chemical production. As industries continue to seek sustainable and renewable alternatives to petrochemical-based products, FDME stands out as a promising candidate for a wide range of applications.

2. Applications of FDME in Polymer Synthesis

The most prominent application of FDME lies in the polymer industry, where it is used as a key monomer in the production of polyethylene furanoate (PEF). PEF is a biobased polyester that is increasingly seen as a sustainable alternative to traditional petroleum-based plastics like polyethylene terephthalate (PET). The production of PEF involves the transesterification polymerization of FDME with ethylene glycol, resulting in a polyester that offers several advantages over PET. These advantages include superior barrier properties against gases like oxygen and carbon dioxide, which makes PEF an ideal material for packaging applications, particularly in the food and beverage industry.

The use of FDME in PEF production is not only beneficial from a performance standpoint but also from an environmental perspective. PEF is derived entirely from renewable resources, which significantly reduces the carbon footprint associated with its production compared to traditional plastics. Additionally, PEF is fully recyclable, aligning with the global push towards a circular economy where materials are reused and recycled rather than disposed of. The incorporation of FDME into PEF also enhances the material's mechanical properties, such as tensile strength and thermal stability, making it suitable for a wide range of applications beyond packaging, including textiles and automotive parts.

Beyond its use in PEF, FDME is also being explored for the production of other types of polymers. Researchers are investigating the potential of FDME to create new classes of polyesters and polyamides, which could offer further improvements in properties such as biodegradability, strength, and resistance to heat and chemicals. These developments highlight the versatility of FDME as a monomer and its potential to drive innovation in the polymer industry. As demand for sustainable materials continues to grow, FDME is poised to play a critical role in the development of next-generation polymers that meet the needs of both industry and the environment.

3. FDME in the Pharmaceutical and Specialty Chemicals Industry

In addition to its applications in polymer synthesis, FDME is gaining attention in the pharmaceutical and specialty chemicals industries due to its unique chemical properties and versatility. As a chemical intermediate, FDME can be used to synthesize a wide range of pharmaceutical intermediates, which are essential building blocks in the production of active pharmaceutical ingredients (APIs). The furan ring in FDME's structure is a key functional group that can be modified in various ways to create complex molecules with specific pharmacological properties.

FDME's stability and reactivity make it an ideal candidate for pharmaceutical synthesis. It can undergo a variety of chemical transformations, including esterification, hydrogenation, and condensation reactions, to produce intermediates with high purity and yield. These intermediates can then be used in the synthesis of drugs that treat a wide range of medical conditions, from chronic diseases to acute infections. The ability to produce pharmaceutical intermediates from FDME also supports the trend towards using bio-based and renewable materials in drug development, which is increasingly important as the pharmaceutical industry seeks to reduce its environmental impact.

Beyond pharmaceuticals, FDME is also used in the production of specialty chemicals, which are high-value chemicals with specific applications in industries such as electronics, agriculture, and coatings. For example, FDME can be used to synthesize bio-based polyols, which are key components in the production of polyurethane foams and coatings. These bio-based polyols offer several advantages over their petrochemical counterparts, including improved sustainability and reduced environmental impact. Additionally, FDME-derived specialty chemicals can be used to create high-performance materials with enhanced properties such as increased durability, flexibility, and resistance to environmental degradation.

英语

英语 中文简体

中文简体