1.What Makes 2,5-Tetrahydrofuran Dimethanol (THFDM) a Game-Changer in Green Chemistry?

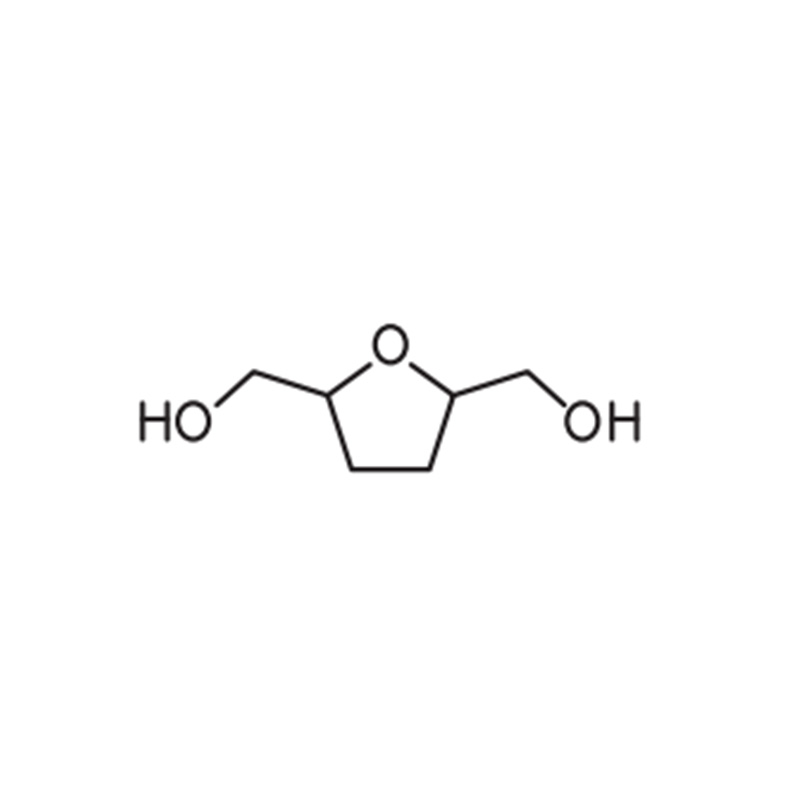

2,5-Tetrahydrofuran Dimethanol (THFDM) is increasingly recognized as a critical innovation in the field of green chemistry, offering a unique combination of sustainability, versatility, and efficiency. As the world pivots towards eco-friendly solutions, the significance of THFDM cannot be overstated. This compound is derived from the saturated hydrogenation of 5-hydroxymethylfurfural (HMF), a process that transforms HMF—a high-value platform molecule—into THFDM, a bio-based solvent with exceptional properties.

One of the most compelling features of THFDM is its green profile. Unlike many traditional solvents that are toxic and harmful to the environment, THFDM is low in toxicity and biodegradable, making it an ideal choice for industries aiming to reduce their environmental footprint. It serves as an effective and sustainable alternative to fossil-based solvents, which are often associated with significant environmental and health hazards. The use of THFDM can, therefore, contribute to reducing the overall impact of industrial processes on the environment, aligning with global trends towards greener, more responsible manufacturing practices.

THFDM’s role as a monomer in the production of bio-based polyesters is another aspect that highlights its importance. Bio-based polyesters produced from THFDM are not only sustainable but also exhibit superior performance characteristics, such as enhanced mechanical properties and thermal stability. This makes them suitable for a wide range of applications, from textiles to packaging, where performance cannot be compromised. As industries increasingly adopt bio-based materials, the demand for THFDM is expected to grow, positioning it as a cornerstone of sustainable manufacturing.

In addition to its application in bio-based polyesters, THFDM also plays a crucial role in the production of high-performance diesel and gasoline additives. Through processes such as esterification and etherification, THFDM can be transformed into additives that enhance the performance of fuels, contributing to better engine efficiency and reduced emissions. This dual functionality—both as a solvent and as a precursor to high-performance additives—makes THFDM a versatile and valuable compound in the quest for more sustainable industrial solutions.

2.Why Is THFDM the Future of Sustainable Bio-Based Materials?

The future of material science is undeniably intertwined with sustainability, and THFDM is leading the charge towards a greener tomorrow. The demand for bio-based materials is surging as industries across the globe seek to reduce their reliance on fossil fuels and minimize environmental impact. In this context, THFDM emerges as a crucial component, offering a sustainable alternative that does not compromise on performance or versatility.

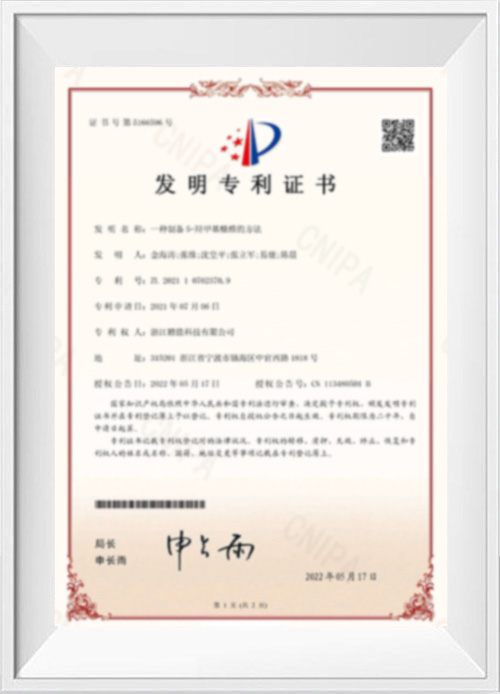

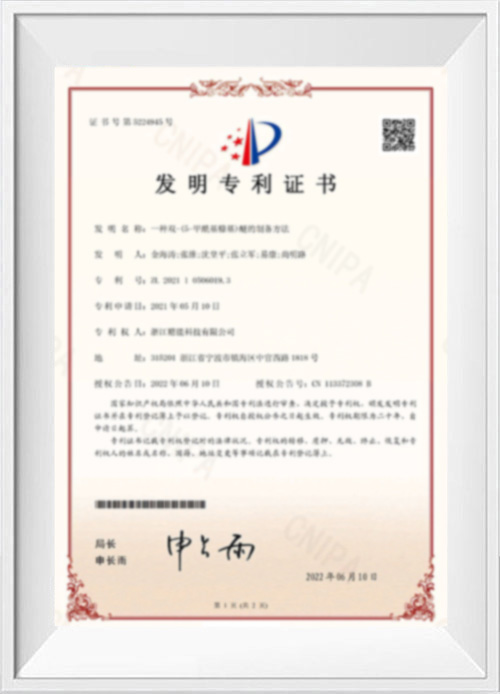

Zhejiang Sugar Energy Technology Co., Ltd. (Sugar Energy Technology), a pioneering company in the field of bio-based materials, has recognized the potential of THFDM and integrated it into its comprehensive portfolio of sustainable solutions. As a national high-tech enterprise, co-founded by the Ningbo Institute of Materials, Chinese Academy of Sciences, Sugar Energy Technology is at the forefront of the research, development, production, and sales of bio-based furan materials. The company’s innovative approach has led to the development of a robust system based on "1 high-end raw material + 5 platform molecules + N high-value products." This system not only ensures the consistent production of high-quality materials but also positions Sugar Energy Technology as a leader in the bio-based materials industry.

THFDM is a key product in this system, embodying the company’s commitment to sustainability and innovation. As a bio-based solvent and monomer, THFDM is derived from renewable resources, making it a greener alternative to traditional petrochemical-based products. Its biodegradability ensures that it does not persist in the environment, reducing the potential for pollution and long-term environmental harm. This makes THFDM particularly attractive to industries that are looking to reduce their environmental impact and meet increasingly stringent regulatory requirements for sustainability.

The versatility of THFDM further underscores its importance in the future of sustainable materials. Its application in the production of bio-based polyesters is just one example of how THFDM can contribute to the development of high-performance, eco-friendly materials. These polyesters, which are used in a wide range of industries, from textiles to packaging, offer the same or even better performance than their fossil-based counterparts while significantly reducing the environmental impact. This ability to combine sustainability with high performance is what makes THFDM a key player in the future of material science.

3.How Is Sugar Energy Technology Revolutionizing the Bio-Based Material Industry?

In a world where sustainability is no longer a choice but a necessity, Sugar Energy Technology is emerging as a trailblazer, revolutionizing the bio-based material industry with its innovative approach and cutting-edge products. The company’s mission, “shaping the beauty of biology and evolving the source of materials,” encapsulates its commitment to driving change in the material science landscape. Through its focus on bio-based furan materials, Sugar Energy Technology is not only contributing to a greener future but also setting new standards for performance and innovation in the industry.

One of the cornerstone products of Sugar Energy Technology is 5-hydroxymethylfurfural (HMF), a versatile platform molecule derived from a wide range of biomass raw materials, including starch, cellulose, sucrose, and agar. HMF’s unique bioactive functional group and aromatic structure give it a distinct advantage over traditional materials, enabling it to enhance the performance of other bio-based materials and expand the possibilities for modifying fossil-based products. This ability to improve and innovate is what sets Sugar Energy Technology apart from its competitors.

The company’s approach to bio-based materials is rooted in a deep understanding of the potential of furan chemistry. By leveraging the inherent properties of HMF and its derivatives, Sugar Energy Technology has developed a comprehensive system that covers the entire material chain. This system, which includes the production of high-end raw materials, platform molecules, and high-value products, ensures that the company can offer a wide range of solutions to meet the needs of various industries. From bio-based solvents to high-performance additives, Sugar Energy Technology’s products are designed to deliver both sustainability and performance.

Sugar Energy Technology’s commitment to research and development is a key driver of its success. The company’s collaboration with the Ningbo Institute of Materials, Chinese Academy of Sciences, has enabled it to stay at the forefront of innovation, continually developing new and improved bio-based materials. This focus on R&D ensures that Sugar Energy Technology can respond to the evolving needs of the market and continue to push the boundaries of what is possible with bio-based materials.

英语

英语 中文简体

中文简体