1.What is 2,5-Tetrahydrofuran Dicarboxylic Acid (THFDCA) and How is it Produced?

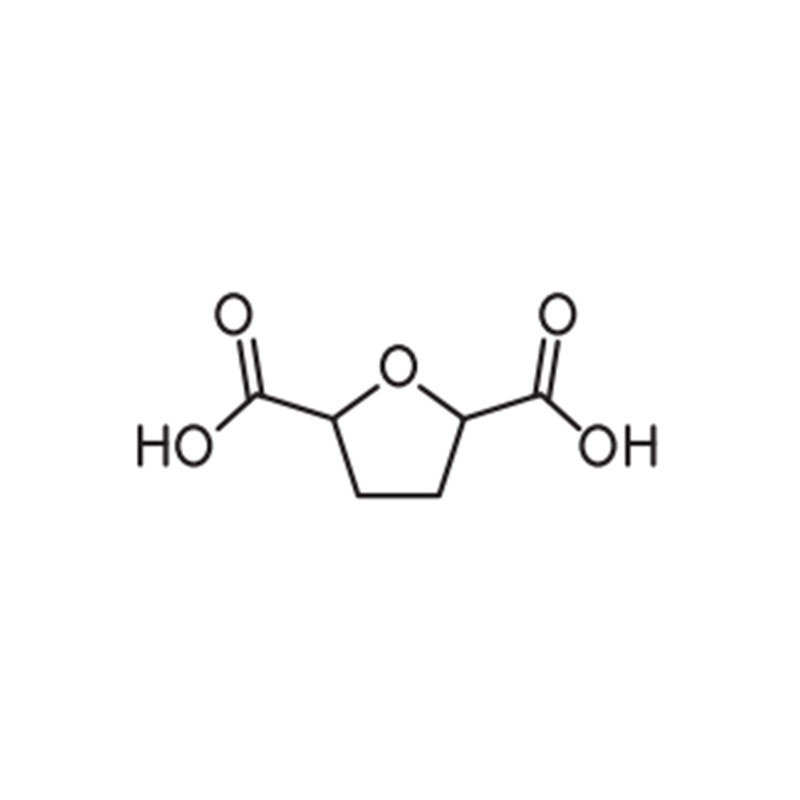

2,5-Tetrahydrofuran dicarboxylic acid (THFDCA) is an exciting and innovative compound in the realm of green chemistry and biobased materials. THFDCA is a saturated furan derivative that has attracted significant attention due to its unique chemical structure and potential applications. It is primarily produced through two main methods: catalytic selective hydrogenation of furandicarboxylic acid (FDCA) and the oxidation of tetrahydrofuran dimethanol (THFDM). Both methods are critical in achieving the high purity and consistency required for industrial use.

The hydrogenation of FDCA is a highly selective process that involves the addition of hydrogen to the furan ring, transforming it into a tetrahydrofuran ring while retaining the dicarboxylic acid functionality. This process typically requires the use of a specialized catalyst that facilitates the selective addition of hydrogen, ensuring that the resulting THFDCA maintains the integrity of the original FDCA structure. The oxidation of THFDM, on the other hand, involves the introduction of oxygen to the molecule, effectively transforming the THFDM into THFDCA through a controlled oxidation reaction. Both processes are designed to produce THFDCA with a high degree of structural fidelity, making it a valuable compound for various industrial applications.

At Zhejiang Sugar Energy Technology Co., Ltd., we have invested heavily in research and development to refine these production processes, ensuring that our THFDCA meets the highest standards of quality and performance. Our production facilities are equipped with state-of-the-art technology that allows us to produce THFDCA at scale while maintaining strict quality control. This commitment to excellence ensures that our THFDCA is suitable for use in a wide range of applications, from polymer production to chemical synthesis.

2.How Does THFDCA Compare to FDCA in Polymer Applications?

In the world of polymer science, 2,5-Tetrahydrofuran dicarboxylic acid (THFDCA) is increasingly being recognized as a promising alternative to furandicarboxylic acid (FDCA). Both compounds share a similar chemical backbone, but THFDCA offers unique advantages that make it particularly suited for certain applications. As a biobased monomer, THFDCA is used in the production of a variety of polymers, including polyesters, polyamides, and polyurethanes, which are critical components in industries ranging from automotive to textiles and beyond.

One of the key benefits of THFDCA is its ability to produce polymers with enhanced mechanical and thermal properties. The saturated nature of the tetrahydrofuran ring in THFDCA provides increased flexibility and durability to the resulting polymers, compared to those derived from FDCA. This makes THFDCA-based polymers particularly suitable for applications where toughness and resilience are required, such as in automotive components, industrial textiles, and high-performance coatings.

The unique structure of THFDCA allows for better compatibility with a wider range of co-monomers, enabling the creation of copolymers with tailored properties. This versatility is highly valuable in the development of next-generation materials that can meet the specific demands of various industries. For instance, THFDCA can be used to produce polyesters with improved biodegradability, making it an attractive option for manufacturers looking to reduce the environmental impact of their products.

At Zhejiang Sugar Energy Technology Co., Ltd., we understand the potential of THFDCA to revolutionize the polymer industry. Our THFDCA is produced with the highest standards of purity and consistency, ensuring that it performs optimally in polymerization processes. We work closely with our clients to provide technical support and guidance, helping them to integrate THFDCA into their existing production lines or to develop new applications that take full advantage of this innovative monomer.

3.Why Choose THFDCA from Zhejiang Sugar Energy Technology Co., Ltd. for Your Synthesis Needs?

When it comes to sourcing 2,5-Tetrahydrofuran dicarboxylic acid (THFDCA), quality, reliability, and sustainability are of paramount importance. At Zhejiang Sugar Energy Technology Co., Ltd., we are proud to offer THFDCA that meets the highest industry standards, making it an ideal choice for a wide range of synthesis applications. Whether you are involved in the production of polymers, chemicals, or pharmaceuticals, our THFDCA provides the performance and consistency you need to achieve your goals.

One of the key applications of THFDCA is in the synthesis of adipic acid, a critical intermediate in the production of nylon and other high-performance materials. Our THFDCA is produced with exceptional purity, ensuring that it can be used in these complex chemical processes with minimal impurities or by-products. This not only improves the efficiency of the synthesis process but also enhances the quality of the final product, making it more competitive in the global market.

In addition to adipic acid, THFDCA can also be used in the production of adipates, which are widely used as plasticizers in the manufacture of flexible plastics. The high purity and consistent quality of our THFDCA ensure that these adipates are produced to the highest standards, providing excellent plasticizing performance in a wide range of applications. This makes our THFDCA a valuable raw material for manufacturers in the plastics industry who are looking to produce high-quality, sustainable products.

英语

英语 中文简体

中文简体