1.What is Poly(ethylene 2,5-furandicarboxylate) (PEF) and How is it Different from PET?

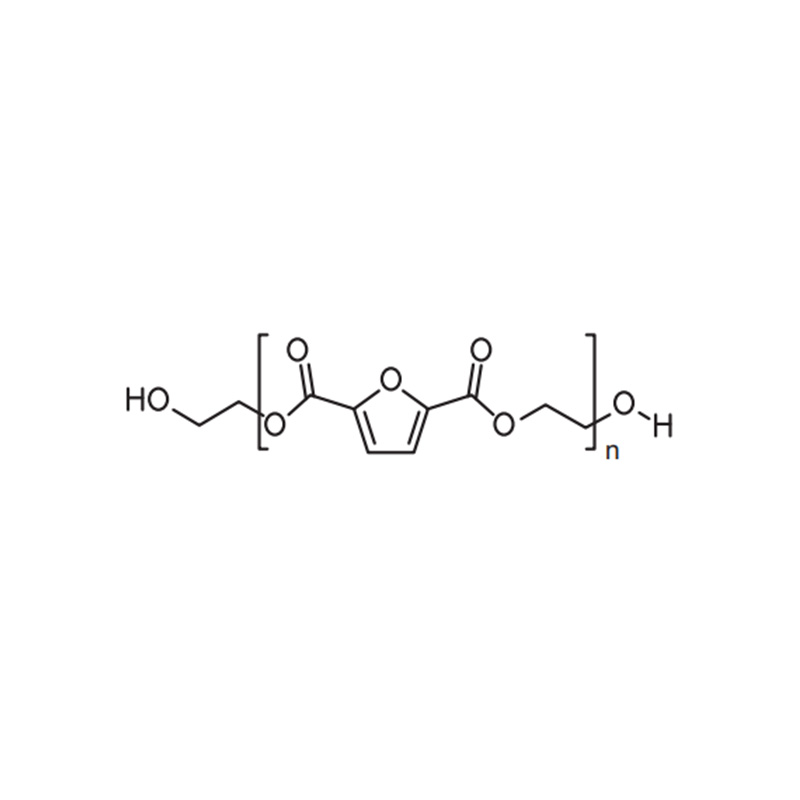

Poly(ethylene 2,5-furandicarboxylate) (PEF) represents a groundbreaking advancement in the field of sustainable polymers. Derived from 2,5-furandicarboxylic acid (FDCA) and ethylene glycol, PEF is a polyester that stands out for its superior properties compared to traditional petroleum-based polyethylene terephthalate (PET). The distinction between PEF and PET lies primarily in the source of their raw materials and their resulting performance characteristics.

PEF is produced from FDCA, which can be derived from renewable resources such as plant biomass. This biobased origin is one of the most significant advantages of PEF, as it aligns with the global shift towards reducing dependence on fossil fuels and lowering carbon emissions. PET, on the other hand, is traditionally synthesized from terephthalic acid (PTA) and ethylene glycol, both of which are derived from petroleum. This makes PEF a more environmentally friendly alternative, contributing to the reduction of greenhouse gases and supporting the circular economy.

Beyond its sustainable origins, PEF offers a range of enhanced properties that make it a superior material in many applications. One of the key advantages of PEF over PET is its improved gas barrier properties. PEF has been shown to have up to ten times better barrier properties against oxygen and carbon dioxide compared to PET. This makes it particularly suitable for packaging applications where the preservation of product freshness and quality is crucial. For instance, in the food and beverage industry, PEF’s ability to limit the permeability of gases can significantly extend the shelf life of perishable goods, reducing food waste and improving consumer satisfaction.

PEF also exhibits a higher resistance to temperature, which makes it more suitable for hot-fill processes compared to PET. Hot-fill applications, common in the packaging of juices, sauces, and other heat-treated products, require materials that can withstand elevated temperatures without deforming or compromising the integrity of the container. PEF’s superior thermal stability ensures that it can maintain its shape and strength under such conditions, offering manufacturers a reliable alternative to PET in demanding environments.

Another area where PEF outperforms PET is in its mechanical strength. PEF's molecular structure provides it with greater rigidity and toughness, which can enhance the durability of the final product. This increased mechanical strength is particularly advantageous in applications that require materials to withstand physical stress, such as in engineering plastics and high-performance fibers. The added strength can lead to thinner, lighter packaging without sacrificing performance, which further contributes to resource efficiency and sustainability.

2.Why is PEF Considered a Breakthrough in High-Barrier Packaging Materials?

Poly(ethylene 2,5-furandicarboxylate) (PEF) has garnered significant attention in recent years as a breakthrough material for high-barrier packaging applications. The packaging industry is constantly evolving, driven by the need for materials that not only preserve product integrity but also align with growing environmental concerns. In this context, PEF stands out for its exceptional barrier properties, which make it a superior alternative to traditional materials like polyethylene terephthalate (PET).

One of the primary reasons PEF is considered a breakthrough in high-barrier packaging is its outstanding ability to limit the permeability of gases such as oxygen and carbon dioxide. These gases are often the culprits behind the degradation of food and beverages, leading to spoilage and reduced shelf life. The superior barrier properties of PEF compared to PET can be attributed to its unique molecular structure, which is more effective at preventing gas molecules from passing through. Studies have shown that PEF has up to ten times better oxygen barrier properties and up to six times better carbon dioxide barrier properties than PET. This means that products packaged in PEF can maintain their freshness and quality for a much longer period, which is crucial in industries like food and beverage.

The extended shelf life provided by PEF packaging has significant implications for both manufacturers and consumers. For manufacturers, it means that products can be distributed over longer distances and stored for longer periods without compromising quality. This can open up new markets and reduce the costs associated with spoilage and returns. For consumers, it translates to fresher products and a reduction in food waste, which is a growing concern worldwide. By extending the shelf life of products, PEF packaging contributes to the reduction of waste and supports more sustainable consumption patterns.

Another critical advantage of PEF in packaging applications is its thermal stability. In the packaging industry, hot-fill processes are commonly used for products such as juices, sauces, and other liquids that are filled into containers at high temperatures. PET, while widely used, has limitations in these applications due to its relatively low thermal resistance. PEF, on the other hand, can withstand higher temperatures without deforming or losing its structural integrity. This makes it an ideal material for hot-fill packaging, where maintaining the shape and durability of the container is essential.

The mechanical strength of PEF also plays a crucial role in its suitability for high-barrier packaging. PEF’s molecular structure provides it with greater rigidity and toughness compared to PET, allowing for the creation of thinner and lighter packaging materials that do not compromise on performance. This not only reduces the amount of material needed but also lowers transportation costs and the overall carbon footprint associated with the packaging. In an industry where sustainability is becoming increasingly important, the ability to use less material while still achieving superior performance is a significant advantage.

3.How Has Zhejiang Sugar Energy Technology Co., Ltd. Advanced the Application of PEF?

Zhejiang Sugar Energy Technology Co., Ltd., a national high-tech enterprise co-founded by the Ningbo Institute of Materials, Chinese Academy of Sciences, has been at the forefront of advancing the application of Poly(ethylene 2,5-furandicarboxylate) (PEF). The company has leveraged its strong research and development capabilities to explore and verify the potential of PEF across various industrial applications, positioning itself as a leader in the development of this next-generation material.

One of the key areas where Zhejiang Sugar Energy Technology has made significant strides is in the application of PEF in the production of fibers. PEF fibers offer several advantages over traditional polyester fibers, including better dyeability, higher mechanical strength, and improved resistance to degradation. These properties make PEF fibers an excellent choice for high-performance textiles, where durability, color fastness, and environmental sustainability are important considerations. The company has successfully completed the verification of PEF fibers, demonstrating their viability for use in a wide range of textile applications, from apparel to industrial fabrics.

In addition to fibers, Zhejiang Sugar Energy Technology has also focused on the development of PEF polyester bottles. The packaging industry is one of the largest consumers of polyester, and the introduction of PEF bottles represents a significant advancement in this field. PEF bottles offer superior barrier properties, which help to extend the shelf life of food and beverages by limiting the permeability of gases. This is particularly important for carbonated drinks and other perishable products that require a high level of protection from oxygen and carbon dioxide. The company’s successful verification of PEF bottles underscores the material’s potential to replace PET in this critical application, offering both performance benefits and a more sustainable alternative.

Another important area of development for Zhejiang Sugar Energy Technology is PEF multilayer films. These films are used in a variety of packaging applications where high barrier properties are essential. PEF’s ability to provide a strong barrier against gases and moisture makes it an ideal material for multilayer films, which are often used to package sensitive products such as food, pharmaceuticals, and electronics. The company has successfully verified the use of PEF in multilayer films, demonstrating its effectiveness in protecting products from environmental factors that can compromise their quality and safety.

英语

英语 中文简体

中文简体